Air suspension for passenger cars comprises air spring, air compressor, solenoid valve block, air reservoir, and ECU. It can be divided into two types (i.e., open-loop and closed-loop), depending on the degree to which it exchanges air with the outside.

In the Chinese market, most OEMs use open-loop air suspension systems, such as VOYAH, LiAuto, XPENG, ZEEKR, LYNK & CO, CHERY, AVATR, and HongQi. This type has high requirements on the air compressor: it needs to compress atmospheric air to about 18 bars quickly and store it in an air reservoir. When lifting the car, the solenoid valve block opens the relevant channel, and the compressed air in the air reservoir fills in the air spring immediately. When lowering the car, the solenoid valve block opens the relevant channel, and the compressed air in the air spring is discharged to the atmosphere directly.

Some car models in the Chinese market, such as IM Motors, HiPhi, and Nio ES8, adopt the closed-loop air suspension systems. This type has compressed air in it. When lifting the car, the air compressor pumps the compressed air in the air reservoir into the air spring. When lowering the car, the air compressor pumps the compressed air in the air spring into the air reservoir.

The open-loop and closed-loop types are quite different in principle, the ASU body structure, air path design, and working mode. Below is a comparison on the structure, principle, noise, lifting/lowering speed, continuous working ability, control difficulty, and high-altitude adaptability.

Type | open-loop system | closed-loop system |

structure and principle | Its air compressor, solenoid valve block, ECU, air reservoir, etc. are standalone, so the system is heavy, costly, and needs more space.

The air path is open to the outside. When lifting the car, the compressed air in the air reservoir fills in the air spring immediately. When lowering the car, the compressed air in the air spring is discharged to the atmosphere directly. | Its air compressor, solenoid valve block, ECU, etc. are integrated, so the system is lightweight, costs less, and does not need much space.

Normally, the air path is not exchanging air with the outside. When lifting the car, the compressed air in the air reservoir is pumped into the air spring. When lowering the car, the compressed air in the air spring is pumped back into the air reservoir. The energy consumption is low. |

noise | The motor power is high. The single working time is long. The air discharge frequency is high. The noise is generally high. | The motor power is low. The single working time is short. The air discharge frequency is low. The noise is generally low. |

lifting/lowering speed | The lifting/lowering speed is about 5 mm/s. | The lifting/lowering speed is slightly lower than that of the open-loop system. |

continuous working ability | The ability to work continuously is poor. Each lifting requires an air compressor to compress the air at 1 atmospheric pressure to about 18 bars. The single working time is long, generating too much heat, which can't be cooled in a timely manner. The ability to work continuously on bumpy roads (e.g., off-road) is poor. | The ability to work continuously is good. Each lifting and lowering requires an air compressor to compress the compressed air at a pressure higher than the atmospheric pressure to about 10 bars. The single working time is short, generating not so much heat, which can be cooled in a timely manner. The ability to work continuously is good. |

design and control | The design is relatively simple, and the control mode is relatively simple. | The design is relatively complex, PWM control is required, and the control mode is accurate. |

high-altitude adaptability. | Since the air filling process requires exposure to the outside, the filling time is much longer in a low-pressure environment. | It is mainly internal circulation. There is little interaction with the outside, The external air pressure basically does not affect the system. |

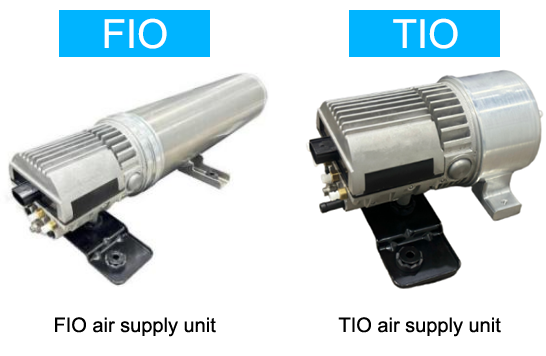

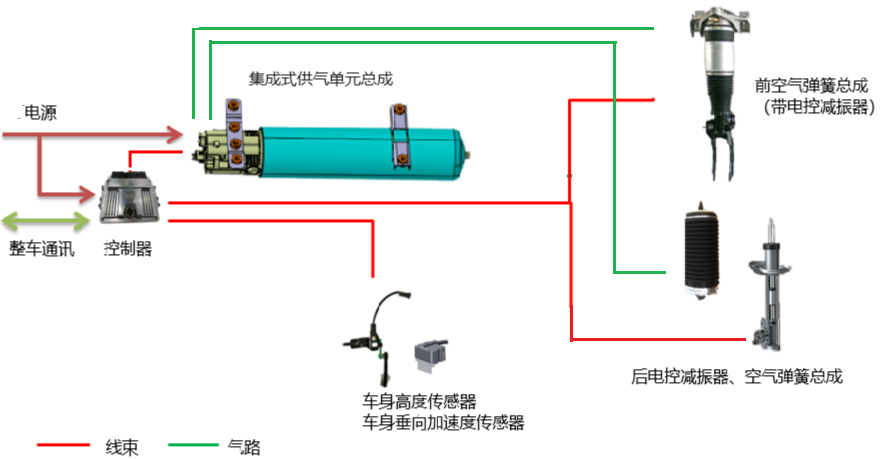

The structure of the closed-loop air suspension system is as follows:

FIO air supply unit & TIO air supply unit

The structure of the closed-loop air suspension system is as follows:

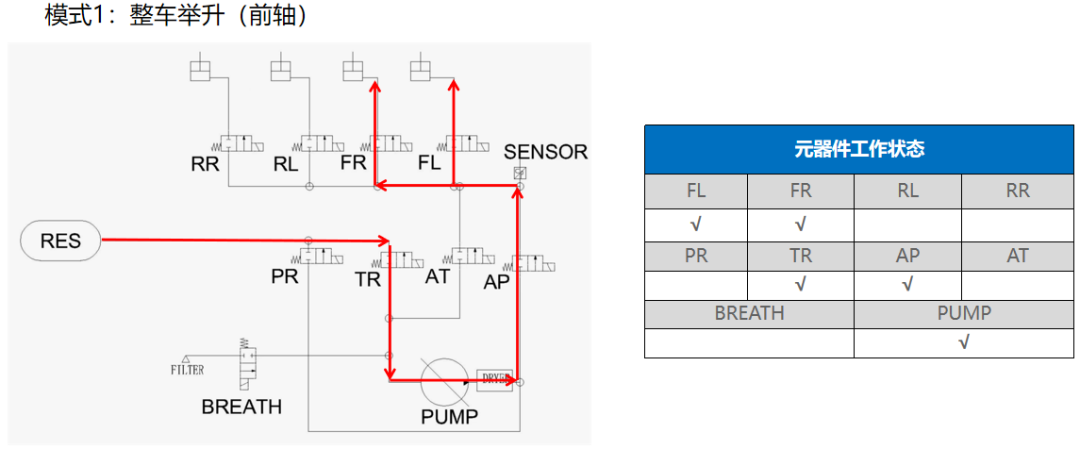

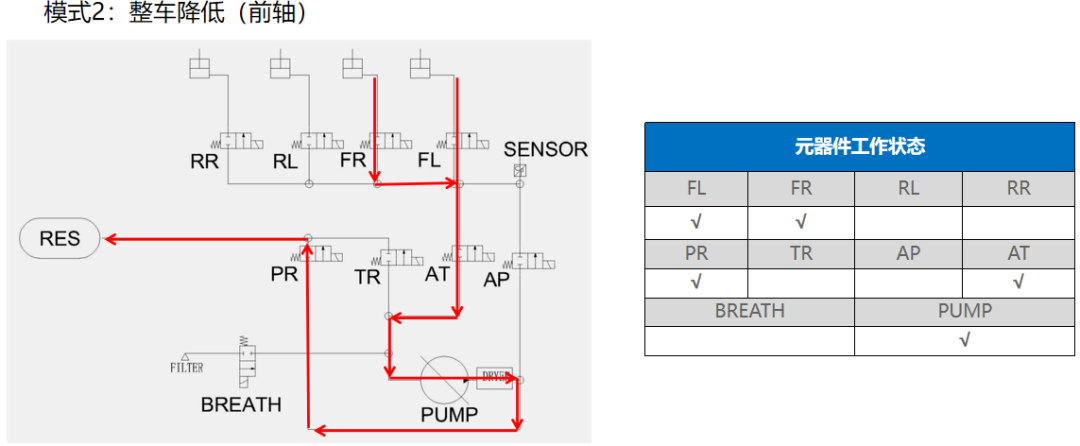

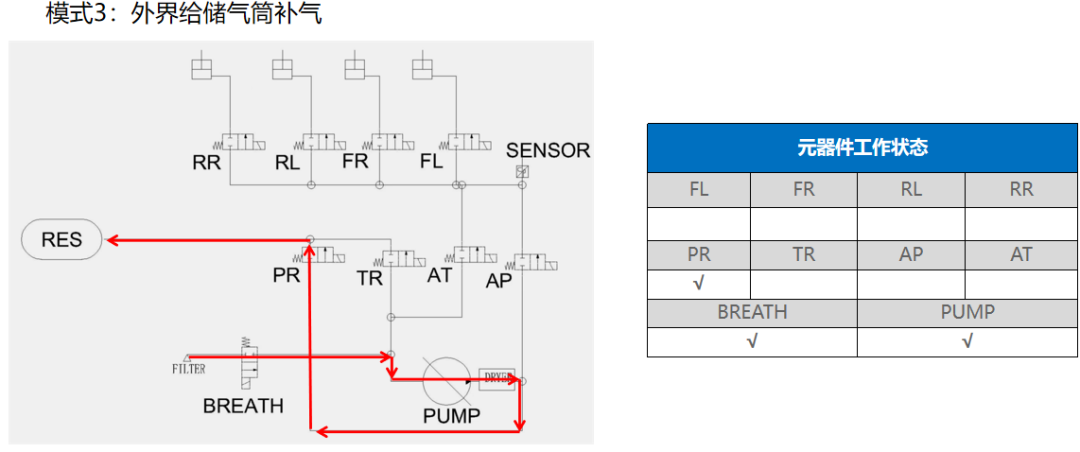

For example, in the case of front axle lifting, front axle lowering, or air supply to air reservoir, the air supply unit of the closed-loop air suspension system works in the following way:

The key performance parameters of the air supply unit of the closed-loop air suspension system are as follows:

No. | Item | Result |

1 | weight | ASU body: 3.9 kg assembly (including ASU body, fixed bracket, 6L air reservoir): about 6.0 kg |

2 | max. working current | working current of the assembly<31A@12V |

3 | dustproof and waterproof | meet IP6K7 and IP6K9K requirements |

4 | max. working pressure in air compressor | 18 bar@12V DC, normal temperature, standard atmospheric pressure |

5 | NVH | noise at 1 meter ≤60 dB |

6 | burst pressure | ≥4.0 MPa |

7 | life of air compressor | ≥1000 h |

KHAT's closed-loop air suspension system is innovative in system structure, control principle, and other aspects. It has filed 3 invention patents and 5 utility model patents and is applying for patents in foreign countries. The mass production of this product will start in the second quarter of 2024 for OEMs, and it will be another cost-effective option KHAT offers to the industry.