We talked about the closed-loop air suspension system last time. In this article, we will introduce dual-chamber air suspension, which is getting popular among Chinese OEMs.

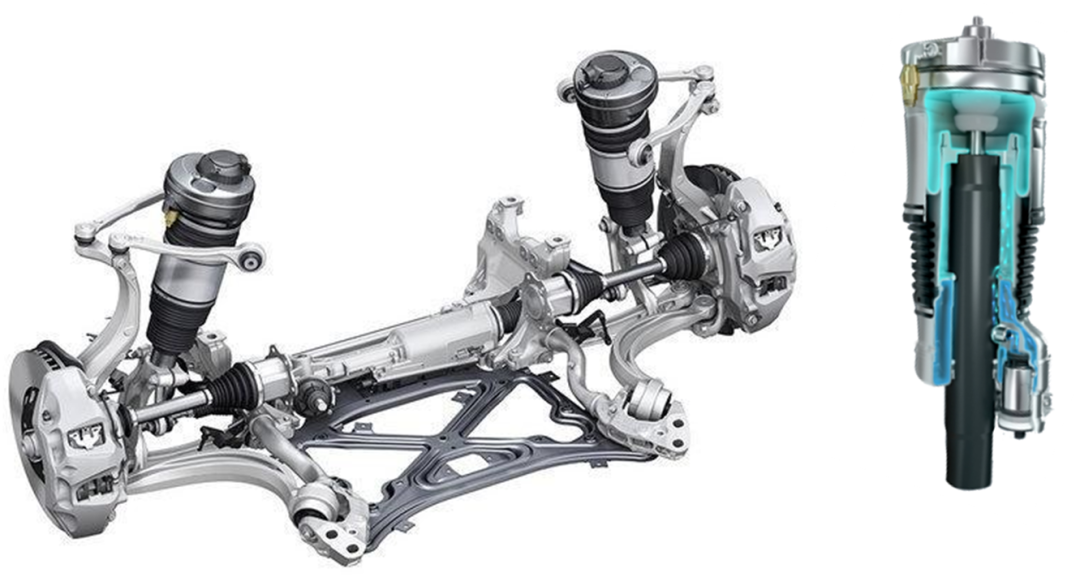

position of air suspension on chassis

The well-designed and tuned air suspension provides a soft and comfortable ride for the driver and passengers on most road surfaces and conditions. In China, the passenger car industry has developed a high interest in the air suspension industry in recent years, and many manufacturers have launched their models, such as LiAuto, Nio, XPENG, VOYAH, ZEEKR, LYNK & CO, Volvo, BYD, HiPhi, IM Motor, AVATR, and CHERY.

The vast majority of domestic car models chose single-chamber air suspension before 2022, but more brands have preferred dual-chamber since 2022 and launched models such as XPENG G9, ZEEKR 009 ME, LYNK & CO 09 EMP, and Volvo EM90.

models equipped with dual-chamber air suspension

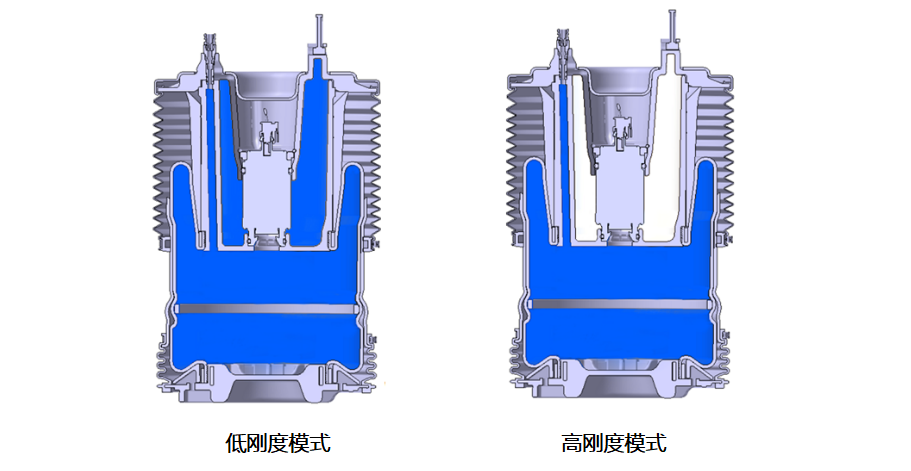

In dual-chamber air suspension, there are main and auxiliary chambers in the air spring, and a solenoid valve opens or closes the only channel between the two chambers. When the channel is open, the main chamber and the auxiliary chamber are connected; the effective working chamber volume is the sum of volume in two chambers; the large volume makes the suspension "soft," and this is the low stiffness mode. When the channel is closed, the auxiliary chamber is no longer the effective working chamber; the effective working chamber volume is only the volume of the main chamber; the small volume makes the suspension "hard," and this is the high stiffness mode. Typically, the difference between the high and low stiffness modes is 40% or 50%.

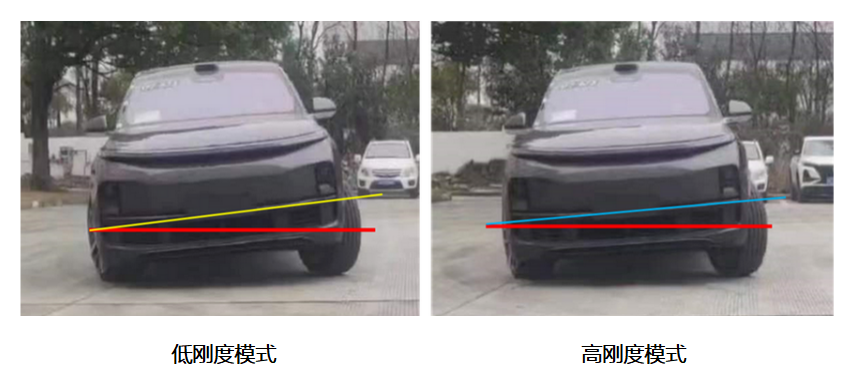

With such significant stiffness difference, the dual-chamber air suspension can be used to improve the car's handling and safety performance. For example, when braking in emergency, the front axle air spring can be switched to high stiffness mode, thereby reducing the degree of forward "dive." When cornering at high speeds, the air spring can be switched to high stiffness mode, thereby reducing the degree of outward tilt. These increase driving safety and smoothness. The pictures below show the difference in outward tilt angle between two modes when cornering at 30 km/h.

comparison of outward tilt angles between the low and high stiffness modes when cornering at 30 km/h

Mode" and "Comfort Mode," respectively, offering different driving styles.

KHAT's "high-performance electronic-control suspension system (dual-chamber structure) assembly for new energy passenger cars" was recognized as China's first piece (set) by the Economy and Information Technology Department of Zhejiang in January 2023. By realizing the SOP of dual-chamber air spring assembly on ZEEKR 009 ME and LYNK & CO 09 EM-P in 2023, KHAT is the first Chinese enterprise to achieve mass production of dual-chamber air suspension.

front dual-chamber air spring assembly for a car model & rear dual-chamber air spring assembly for a car model

As of January 2024, KHAT has supplied more than 7,000 pieces (sets) of dual-chamber air spring and been nominated for mass production for 14 car models. It is predicted that the installed capacity of dual-chamber air suspension will be about 30% and over 50% of the total installed capacity of air suspension in the Chinese market in 2024 and 2025, respectively.