In this article, we will discuss why dry air is needed in the air path in air suspension, as well as the important functions of air suspension dryers: water absorption and regeneration.

The air suspension system of passenger cars can be open-loop or closed-loop, depending on the air path. In an open-loop system, the atmospheric air is compressed and stored in the air reservoir. When lifting the car, the air reservoir usually provides compressed air (if the air pressure in the air reservoir is insufficient, the air compressor directly supplies air) to the air spring. When lowering the car, the excess compressed air is discharged to the atmosphere. Therefore, the open-loop system needs to often replenish air from the outside.

In a closed-loop system, air is generally circulated internally, and it is also replenished from the outside when the system pressure falls below a certain threshold. The replenishment happens about every 10 to 15 days, depending on the speed of system leakage.

However, the atmospheric air contains vapor, more or less. If it is not properly controlled, it will cause a lot of trouble to the air suspension. For example, water freezing at low temperatures will block the air path, so that the car cannot be lifted or lowered. Moisture will accelerate the corrosion of ASU parts and even cause the air compressor to stall, compromise the function of the stiffness valve (on dual-chamber air spring), etc. Therefore, the air suspension system needs to include a dryer with good water absorption and regeneration capacity.

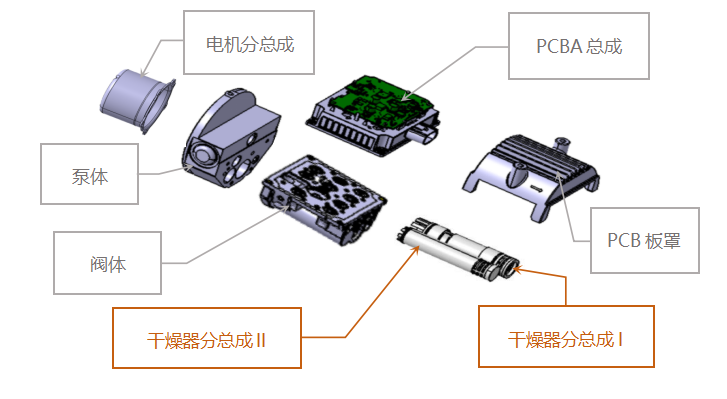

closed loop ASU structure

The water absorption capacity of the dryer is related to the properties of the desiccant material. When water absorption reaches a saturated state, the dryer cannot absorb water any more. That's why regeneration is important. To put it simply, regeneration refers to the function of completely or partially discharging the water absorbed by the dryer out of the air suspension system and restoring the dryer's ability to absorb water.

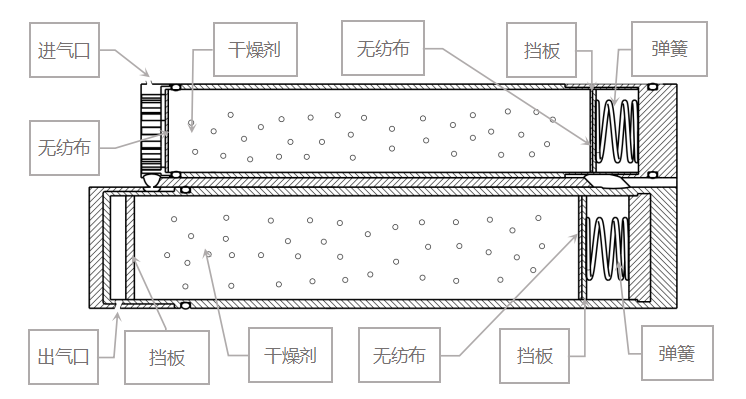

Let's take a look at the principle of water absorption and regeneration in the dryer.

The dryer is filled with desiccant (97% SiO2 + 3% Al2O3) and has good water absorption capacity. Desiccant is a porous substance with a large specific surface area, its water absorption saturation rate (weight of water absorbed by desiccant/weight of desiccant) is above 30%, which can effectively absorb water in the air suspension system and keep the system relatively dry.

A good air suspension system usually can automatically regenerate desiccant by electric control, rather than replacing the desiccant manually. The manual method is not only time-consuming and labor-intensive but also difficult to restore the water absorption capacity in time. Considering that new energy vehicles generally don't have many maintenances at the dealership, if systematic regeneration cannot be achieved at the right time, there is no guarantee that the air path is dry. The principle of automatic regeneration is to heat the desiccant at regular intervals to evaporate water molecules and then open the valve to let the compressed air blow water molecules out of the system, so as to reduce the desiccant saturation rate and restore the water absorption capacity.

cross-section view of the dryer

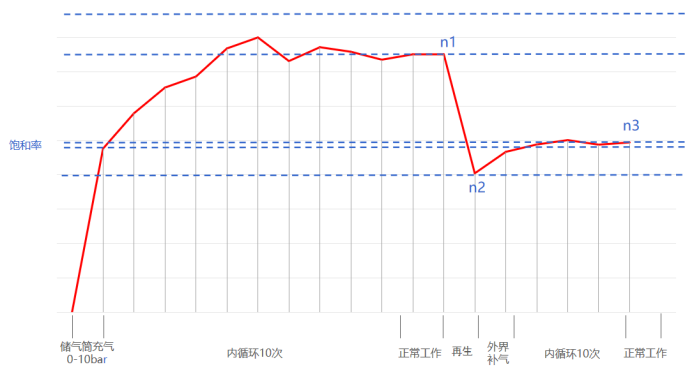

After 3 years of research that starts from scratch (including the design and development of appearance, interior, power system, platform, etc.) and continuous optimization, KHAT has developed closed ASU with good water absorption and regeneration capacity and been nominated for 4 car models, including a Shanghai joint venture. The following is the test method and results of regeneration capacity in the dryer of closed ASU, while real use cases are simulated:

Step 1: Fill air from outside to the air reservoir until the pressure reaches 10 bars.

Step 2: Run 10 cycles in the air suspension system and record the saturation rate "n1" after the desiccant absorbs water.

Step 3: Heat to regenerate, and record the saturation rate "n2" after the desiccant absorbs water.

Step 4: Take air from the outside to replenish the amount of air regenerated.

Step 5: Run 10 cycles in the air suspension system and record the saturation rate "n3" after the desiccant absorbs water.

test results of water absorption and regeneration capacity in the dryer of the closed ASU

As shown in the figure above, "n1-n2" represents the water absorption capacity restored after the water is blown out of the system. However, in order to ensure the air pressure in the system, additional air must be added from the outside at this time, and the moisture in the air will increase the saturation rate of the desiccant, so the reabsorbed water must be less than the water just discharged to make the regeneration effective. The difference between the saturation rate after water absorption "n1" and the saturation rate after water discharge and air replenishment "n3" is the regeneration capacity of the system. It must be greater than 0, and the larger the value, the better.

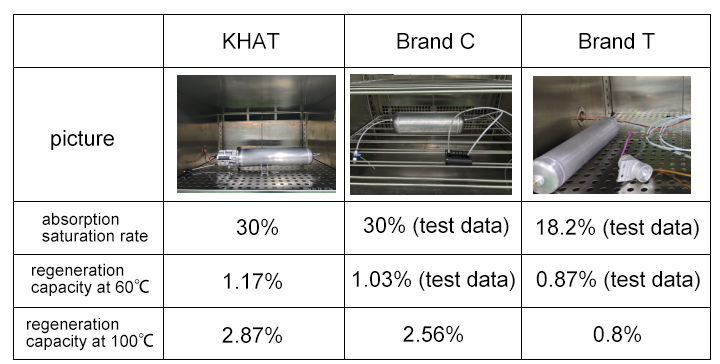

The following table is a comparison of the water absorption and regeneration capacity of ASU from KHAT and two other brands:

After testing and comparing many dryers of ASU, KHAT drew a conclusion: according to the principle of dryer described in this article, the dryer of the air suspension system needs to be integrated with the ASU body as much as possible or close to the heat source in order to make regeneration effective; otherwise, the dryer may not be working.